With an ultrafast laser-based technology that scientists have devised for fabricating surfaces without the need of coatings or further surface treatment, eco-friendly self-cleaning surfaces that can safeguard biomedical and other applications from rusting and bacterial development may soon be a reality.

Super-hydrophobic functional surfaces

Surfaces with anti-wetting and anti-staining capabilities have piqued the interest of academics from both the fundamental development and application sides of the challenges, as well as a variety of commercial and academic stakeholders.

Since the early 2000s, the number of scientific works in this sector has increased dramatically, and multiple reviews have been published in this field highlighting various characteristics of these surfaces.

Superhydrophobic surface theory

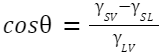

Wetting regimens and contact angle

The angle at which the liquid–vapour interface meets the solid–liquid interface is known as the contact angle (). The contact angle of the water droplet determines the wettability of the flat surface, which is provided by Young’s equation:

The superhydrophobic surfaces application landscape can be widely characterised. Metals, glass, polymers, composites, and micro- and nanoparticles are among the materials that are produced and chemically processed to create products for use in a variety of commercial and research-based settings.

The functional needs in domains relevant to some of the sectors, such as automotive, aerospace, maritime applications, medical devices, nuclear reactors, textiles, clinical diagnostics, and sensing, drive the majority of research on superhydrophobic surfaces and coatings.

Superhydrophobic surfaces boost the functional performance of some work systems significantly above their traditional equivalents. The next paragraphs go through some of the fundamental applications.

Uses in the field of energy storage devices

According to Lifton et al., superhydrophobic nanostructured materials are directly linked to battery performance increase.

Surface-treated nanostructured silicon electrodes with superhydrophobic properties have been developed, allowing the active electrode materials to be effectively separated from the liquid electrolytes, resulting in extremely high interfacial capacitance and the ability to act as ultra-high storage centres. Bok and colleagues

A single-step process developed by ARCI scientists

Surface modification with a femtosecond laser (lasers produce light pulses with durations sometimes between femtoseconds and hundreds of femtoseconds, i.e. 10-15 of a second), non-thermal, & eco-friendly is the single-step approach created by ARCI scientists.

The process will be scalable in terms of reducing cycle time and applying the advanced hierarchical micro-scale and nano-scale structures over massive swaths for practical applications in corrosion prevention, bacterial growth prevention, and avoiding repeated cleaning thanks to the efficient and straightforward strategy.

Currently, superhydrophobic qualities are accomplished by creating rough surfaces and chemical coatings with low surface free energy, which are typically two-step procedures.

However, there are a number of drawbacks to superhydrophobic coating surfaces, including the usage of fluorinated hazardous reagents and low mechanical stability.

This technology allows for fine control of the structural pattern and tailoring of the contact angle and wetting characteristics of a range of substrates by modifying the laser processing settings.

It is a robust, simple, fast, precise, and environmentally friendly process that can be used to fabricate robust superhydrophobic surfaces and has a lot of potential for large-scale use.

Super-hydrophobic coating surfaces

A superhydrophobic coating is a water-repellent thin surface layer. It is composed of materials that are superhydrophobic (ultrahydrophobicity). Droplets hitting this type of coating can bounce back completely.

In general, superhydrophobic coatings are made up of two components: one that gives roughness and the other that offers low surface energy.

Super-hydrophobic coatings are employed in ultra-dry surface applications in industry. A nearly imperceptibly thin layer of air forms on top of a surface as a result of the coating. In nature, super-hydrophobic coats may be found on plant leaves, such as the Lotus leaf, and insect wings.

To make items waterproof, the coating can be sprayed over them. The spray is anti-corrosive and anti-icing, as well as cleaning and protection for circuits and grids.

The marine sector uses superhydrophobic coatings extensively. They can reduce skin friction drag on ship hulls, resulting in increased fuel economy. Ships with such a covering might boost their speed or range while saving money on fuel. They can also help to prevent corrosion and the growth of marine organisms on a ship’s hull.

In addition to these industrial applications, superhydrophobic coatings might be used to prevent rain droplets from adhering to car windshields. The coatings also allow salt deposits to be removed without the need of freshwater. Furthermore, superhydrophobic coatings can help in mineral extraction from saltwater brine.

Despite the coating’s numerous uses, environmental and worker safety are concerns. [needs citation] The International Maritime Organization has a number of rules and policies in place to protect water from potentially harmful additions.

The repellency of superhydrophobic coatings is based on a thin micro or nanostructure that is quickly broken by abrasion or washing; as a result, the coatings are fragile.

Conclusion

Eco-friendly self-cleaning surfaces that can protect biomedical and other applications from rusting and bacterial development may soon be a reality thanks to an ultrafast laser-based technology developed by scientists for fabricating surfaces without the need for coatings or further surface treatment. Academics from both the basic development and application sides of the issues, as well as a number of commercial and academic stakeholders, are interested in surfaces with anti-wetting and anti-staining qualities.

Profile

Profile Settings

Settings Refer your friends

Refer your friends Sign out

Sign out