In material science and engineering, we always try to know more about the behaviour of a rigid body when it goes through stretching, twisting and squeezing. We make our effort to understand the behaviour of rigid bodies by establishing a relation between applied force and deformation. So to understand the mechanical properties of a substance, we have first to understand stress and types of stress.

Stress is defined as the internal restoring force per unit area. Let us take an example. If we apply a force on a rubber wire, it elongates. After a while, when we remove the force, then the rubber regains its original shape and size. Now the question is, what is the responsible force which drives back the rubber to its original position? It can be explained like this: An internal force is developed when we apply the external force. The magnitude of this restoring force increases as the elongation of wire increases. When we remove the external force, the rubber wire returns to its original shape and size due to that restoring force. So stress is the restoring force per unit area that acts inside the body.

Formula for stress

As we discussed, stress is restoring force per unit area, So mathematically,

Stress =FA

where,

F is restoring force

A is the surface area to which F is perpendicular

Some important points on stress

- Stress is a tensor quantity

- Unit of stress is Nm-2

- Dimension [M1L-1T-2]

Unit of stress

In the SI unit, the unit of stress is Nm-2 or Pascal. However, this unit of stress is minimal, and thus, in engineering applications, some larger units are used. They are MPa and GPa-

1MPa=106Pa=1N/mm2

1GPa=1000MPa=1KN/mm2

Types of stress

In border sense, various types of stress can classify as-

Simple or Direct stress

- Simple or direct stress can be defined as the stress produced due to direct loading.

- Example: When a heavy mass is suspended by a rod. Due to the weight of the mass, it applied force on the rod and produced stress in the rod.

- This includes tension, compression and shear stress.

Indirect stress

- When a load is applied on a body and the body deformed, deformation stress is produced. This type of stress is called indirect stress.

- Indirect stress includes bending.

Let us understand these stresses in more detail.

- Tensile and compressive stress: Tensile or compressive stress is applied perpendicularly per unit area. Tensile stress is defined for tension force, whereas compressive stress is defined for compressive force.

Stress = FA

where F is the magnitude of the force perpendicular to the area A. - Shear stress: Shear stress is also force per unit area, but here the force vector is not perpendicular to the surface. The force vector lies on the plane of the area. Alternatively, we can define the force as tangential to a given surface area.

Shear stress=FA

where F is the magnitude of the force acting tangential to the surface having area A. - Volumetric Stress: If we apply force on the total volume of a body, it is known as volumetric stress. Let us take an example. When a body is submerged in water, a hydrostatic force acts on the total surface, which is a type of pressure force too. So this pressure force per unit area is called volumetric stress.

- Bending stress: When a load is applied perpendicular to the axis of a body or a couple of forces acting in a plane passing through the axis, they cause bending. The stress developed due to bending is called bending stress.

Problem on stress

Problem 1

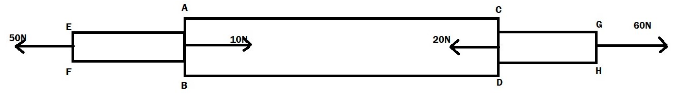

Given figure forces on each cross-section are shown. The surface area of cross-sections is like the area of AB=Area of CD=2mm2, Area of EF= Area of GH=1mm2. Then find the stress on the surface AB, GH, EF and CD.

Solution:

- If we start to analyse from the left side then, Net force on the left side of AB=50-10=40N

Hence total load on either side of AB=40N (positive sign means tensile force )

Surface area of AB= 2mm2

Hence stress on AB= 402N/mm2= 20MPa

- Similarly, the net force on the right side of GH= 60N

As the rod is in equilibrium, then we can say that the Total force on either side of the surface GH= 60N

Surface area GH= 1mm2

Hence stress on GH= 601N/mm2=60 MPa

- Force on right side of CD= 60N

Surface area of CD= 2mm2

Hence stress on CD= 602N/mm2= 30MPa

- For surface EF similar manner, we can calculate the force that is 50N

Surface area EF= 1mm2

Hence stress on EF= 501N/mm2=50 MPa

Problem 2

A balloon is filled with air having an internal pressure of 3Pa. The diameter of the balloon is 4cm. Then find the volumetric stress.

Solution:

As the balloon is in equilibrium, its volume is constant and the total force on either side of the surface is the same. Hence pressure is equal to the volumetric stress here.

Hence volumetric stress = 3Pa

Conclusion

There are various studies and applications of stress in material engineering and science. By the information of stress on a body, we can calculate the elongation produced on the body. When the stress on a material increases, various changes that are described by various limits can be explained based on stress-strain diagrams. By using Hooke’s law, we can derive Elastic constants from stress information.

In this study material, we discussed stress, types of stress and solved some stress-related questions.

Profile

Profile Settings

Settings Refer your friends

Refer your friends Sign out

Sign out