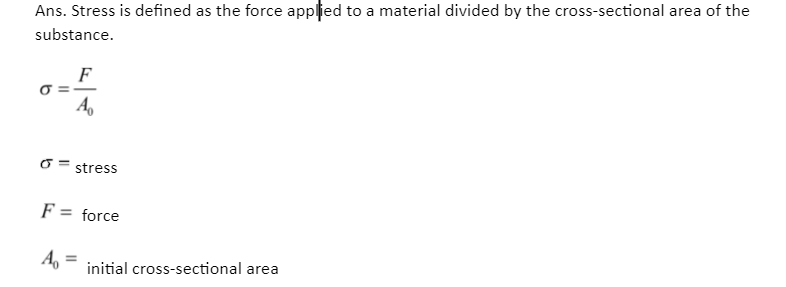

Stress

Stress is defined as the force applied to a material divided by the cross-sectional area of the substance.

stress

force

initial cross-sectional area

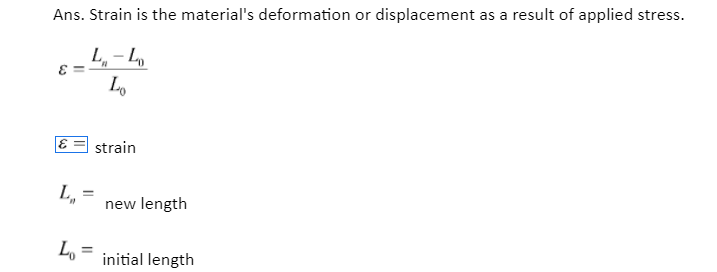

Strain

Strain is the material’s deformation or displacement as a result of applied stress.

strain

new length

initial length

Young’s modulus

Young’s modulus is a numerical constant named after Thomas Young, an 18th-century English physician and physicist, that describes the elastic properties of a solid undergoing tension or compression in only one direction, such as a metal rod that returns to its original length after being stretched or compressed lengthwise. Young’s modulus is a measurement of a material’s ability to endure length changes when subjected to lengthwise tension or compression. Young’s modulus, often known as the modulus of elasticity, is equal to the longitudinal stress divided by the strain. In the instance of a metal bar under tension, stress and strain can be described further in this article.

Young’s modulus Formula

When a force F is applied to each end of a metal bar with cross-sectional area A, the bar stretches from its original length to a new length

. (At the same time, the cross section shrinks.) The quotient of the tensile force divided by the cross-sectional area, or F/A, is the stress. The change in length,

, divided by the original length, or

, is the strain or relative deformation. (Strength has no dimensions.)

Mathematically, Young’s Modulus is expressed as:

Young’s modulus (E) =

This is a specific form of Hooke’s law of elasticity.

Young’s Modulus is denoted by E.

Calculation of Young’s Modulus

Young’s modulus calculations are based on the applied force, the kind of material, and the material’s area. The stress in the medium is proportional to the applied force divided by the cross-sectional area. In addition, the strain takes into account a material’s change in length compared to its original length.

To begin, you must determine the substance’s starting length. You determine the cross-sectional area of the material with a micrometre. Then, using the same micrometre, measure the substance’s various diameters. Then, using a variety of slotted masses, calculate the applied force.

Use a Vernier scale to calculate the length of the components because they extend at different lengths. Finally, plot the various length metrics in relation to the applied forces. E = tensile stress/tensile strain = (FL) / (A * change in L) is the Young’s modulus equation, where F is the applied force, L is the initial length, A is the square area, and E is the Young’s modulus in Pascals (Pa).

Applications for Young’s Modulus

Using Young’s modulus calculations, tensile testing aids in determining the stiffness of materials. Take a rubber band for example. When you stretch a rubber band, you are exerting force on it. The rubber band eventually bends, deforms, or breaks.

Tensile testing assesses the elasticity of various materials in this way. This classification primarily distinguishes between elastic and plastic behaviour. As a result, the materials are elastic when they deform sufficiently to return to their original state. A material’s plastic behaviour, on the other hand, reveals a non-reversible deformation.

An ultimate strength rupture point happens when materials are subjected to a large amount of force. Different materials have different Young’s modulus values. Nylon, for example, has a greater Young’s modulus of 48 MegaPascal (MPa) in experimental tensile testing, indicating that it is a good material for making strong elements. Alumide, glass-filled nylon, and carbonmide all have a Young’s modulus of 70 MPa, making them suitable for even tougher components. These materials, as well as tensile testing, are used in modern medical technology to manufacture safe implants.

Characteristics of Young’s Modulus

One of the most important tests in engineering is determining when an object or material will bend or break, and the characteristic that tells us this is Young’s modulus.

The ratio of tensile stress ( ) to tensile strain (

) is defined as Young’s modulus (E), a material property that indicates how easily it can stretch and flex.

The stress-strain curves for several materials may appear to be quite dissimilar. Brittle materials are exceptionally strong because they can withstand a great deal of stress, stretch little, and fracture quickly. Plastic materials are not particularly durable, but they can withstand a lot of stress. Young’s modulus is represented by the gradient of a line in a stress-strain diagram.

Material mechanical characteristics research is important because it helps us understand how materials behave and allows us to create new products and improve existing ones.

On a microscale, many things comprise both biological and non-biological microparticles (e.g., pharmacological drugs, reproductive therapies, tissue engineering) (e.g. chemicals, agriculture, household care). We can foresee their behaviour in manufacturing and processing by understanding their mechanical properties, allowing us to maximise their performance potential.

A material’s Young’s modulus is a crucial property to know in order to predict how it will react when subjected to a force. This is crucial for virtually everything in our environment, including buildings, bridges, autos, and more.

A substance’s Young’s Modulus is an immutable fundamental property of all materials. Temperature and pressure, on the other hand, play a role. The stiffness of a material is defined by its Young’s Modulus (or Elastic Modulus). To put it another way, how easily it bends or stretches.

Conclusion

Due to applied forces or motion, every component in a linear motion system is loaded in some way. The mechanical properties of the component define how it reacts to these loads.

The stress-strain charts for various materials might seem very different. Brittle materials are robust because they can endure a great deal of stress, don’t extend much, and break quickly. The stress-strain relationship in ductile materials is linear in the elastic zone, but the linearity breaks down at the first turnover (the elastic limit), and the material can no longer return to its former form.

The ultimate tensile strength is the second peak, and it informs us how much stress a material can bear before breaking. Plastic materials are not particularly strong, yet they can withstand a great deal of stress. The gradient of the line in a stress-strain plot determines Young’s modulus.

Profile

Profile Settings

Settings Refer your friends

Refer your friends Sign out

Sign out