When exposed to external forces, a rigid body model is an idealised demonstration of an item that does not deform. It’s particularly useful for assessing mechanical systems, as many physical objects are quite stiff. The physical features of the material used to create an item determine the degree to which it can be considered stiff. When squashing pressures are applied to a plastic ping-pong ball, it becomes brittle, whereas a rubber tennis ball becomes elastic. A ping-pong ball and a tennis ball, on the other hand, may both bounce also as rigid bodies in other situations.

Deformation

A deformation is a change in shape that occurs when a force is applied. It is well known that even minor stresses can cause some deformation. External pressures such as squashing, pressing, tearing, twisting, shearing, or pulling apart cause deformation in objects or physical mediums. In physics, two words describe the forces acting on objects that are deforming: stress and strain.

Stress: The amount of the force that causes deformation is measured by stress. Stress is defined as force applied per unit area in general.

Types of stresses:

Tensile stress: When forces pull on an object and cause it to extend, such as when an elastic band is stretched, then that stress is called tensile stress.

Compressive stress: When stresses cause an item to compress, this is known as compressive stress.

Bulk stress: When an item is squeezed from all sides, such as with a submarine in the ocean’s depths, bulk stress arises (or volume stress).

Strain: When a material or object is subjected to stress, it deforms. The quantity that describes this distortion is called strain. When under tensile stress, strain is indicated as a fractional change in length, volume (when under bulk load), or shape (under shear stress). As a result, strain is a number that has no dimensions.

Types of strain:

Tensile strain: When the strain is caused as a result of tensile stress then the strain is called tensile strain.

Bulk strain: when the strain is caused as a result of bulk stress then the strain is called bulk strain.

Shear strain: when the strain is caused as a result of shear stress then the strain is called shear strain.

Elastic constants

The elastic constants are the constants that determine how much deformation a certain stress system causes in a material. Bulk modulus, Young’s modulus, or modulus of elasticity, Poisson’s Ratio, and Shear modulus, or modulus of rigidity, are examples of elastic constants. When a deforming force occurs on a solid, the original dimension of the solid shifts. The relation between elastic constants can be utilised to determine the amount of deformation in such cases.

Hooke’s law

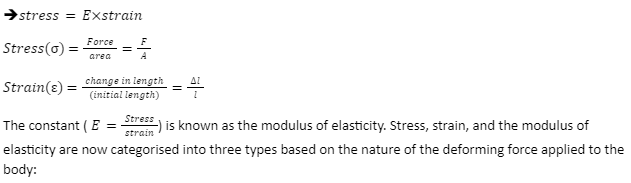

“For tiny deformations, the stress in a body is proportional to the associated strain,” according to Hooke’s law.

stress α strain

- Young’s modulus

- Bulk modulus

- Modulus of rigidity

Young’s modulus (Y)

Young’s Modulus, sometimes called Elastic Modulus or Tensile Modulus, is a mechanical characteristics measurement of linear elastic solids like rods and wires. Other numbers exist that provide us with an estimate of a material’s elasticity. Two examples are bulk modulus and shear modulus. The value of Young’s Modulus, on the other hand, is the most usually used. This is due to the fact that it offers data about a material’s tensile elasticity.

Elastic deformation occurs when a material is compressed or stretched, and it returns to its original position when the load is released. When a flexible substance deforms, it deforms more than a hard substance. In other words, it can be read as follows:

- Elastic material is defined as a solid having a low Young’s modulus value.

- Inelastic or stiff is a solid with a high Young’s modulus value.

Bulk modulus (B)

When we apply uniform pressure to a body’s surface, the volume of the body varies, and this change in volume per unit volume of the body is referred to as the volume strain, while the normal force acting per unit area of the surface is referred to as the normal stress or volume stress. The bulk modulus of the body material is defined as the ratio of the volume stress to the volume strain for small strains.

Modulus of rigidity ()

When an external force is applied tangentially to a body surface while the opposing surface remains fixed, the shape of the body changes, but the volume remains unchanged. The force is applied to the face, which is displaced in the direction of the imparted force. Shear strain arises in the material as a result of this. Shearing stress is the tangential force acting per unit area of the surface, and shearing strain is the ratio of the displacement of a layer in the direction of the tangential force and the distance of the layer from the fixed surface. The ratio of the shearing stress to the shearing strain of the body’s material is known as the modulus of stiffness.

Conclusion

Stress is defined as force per unit area, whereas strain is defined as elongation or contraction per unit length. We define three elastic moduli: Young’s modulus, shear modulus, and bulk modulus, to characterise the elastic behaviour of things as they respond to deforming forces acting on them. The modulus of elasticity is the ratio of stress to strain.

Profile

Profile Settings

Settings Refer your friends

Refer your friends Sign out

Sign out