In chemistry, catalysis is defined as a change in the rate of a chemical reaction, usually, an amplification, caused by the addition of a substance that is not consumed during the process. The velocities at which chemical reactions occur are determined by a variety of factors, including the chemical composition of the reacting species and the external factors to which they are exposed. This process can be further divided into two types: homogeneous and heterogeneous catalysis. Catalysts are chemicals that facilitate catalysis but are not metabolised in the reactions themselves.

Heterogeneous Catalysis

There are several catalytic processes where the catalyst and reactants are not in the same phase or state of matter. Heterogeneous catalytic reactions are the name for such a category of reactions. At the surface of a solid catalyst, the reaction includes interactions involving gases, liquids, or both. Heterogeneous catalysis reaction is defined as the ability of solid surfaces to form and break bonds with molecules from their surroundings. Solid surfaces catalyse a wide range of chemical processes. This applies to most large-scale chemical processes in industry as well as a number of environmental protection activities, such as automobile exhaust gas cleaning, etc.

Surface Reactions

Reactions on surfaces are reactions in which the adsorption of one or more reactants is one of the steps in the reaction mechanism. For a heterogeneous catalysis reaction to occur, the mechanisms for the reaction, as well as the rate equation, are critical. For reaction A + B → C, there are two popular processes for surface reactions that can be stated. The first is the Langmuir–Hinshelwood mechanism, which states that both A and B reactant molecules adsorb to the catalytic surface. They combine while adsorbed on the surface to generate product C, which then desorbs. In the Eley–Rideal pathway, one substrate molecule, A, adsorbs on the catalytic surface. In the second step, B interacts with absorbed A without being adsorbed to create C, which then desorbs from the surface without adsorption.

Fig 1: Reaction Coordinates of (A) Uncatalysed (B) Catalysed ( C) Catalysed with discrete intermediates

Catalyst Design

Heterogeneous catalysts and adsorbent materials are custom-made materials that must meet a number of criteria. They usually have porous designs to provide for as much surface area as feasible for adsorption and/or (electro-) catalytic transformation. The outside appearance or morphology of heterogeneous catalysts and adsorbents, in addition to their interior structure, performs an essential function in their overall performance.

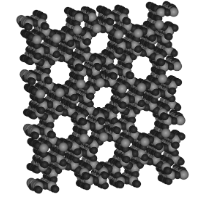

Figure 2. Zeolite Structure

Catalyst Deactivation

Deactivation of a catalyst occurs when it loses its catalytic activity and/or selectivity after a certain age. Poisons are substances that slow down the rate of reaction. Poisons chemisorb to the surface of the catalyst, reducing the number of active sites available for reactant molecules to attach to. Sulphur, oxygen, phosphorus, chlorine, and other Group V, VI, and VII elements, as well as hazardous metals such as arsenic and lead, are common toxins. Catalyst deactivation, or the loss of catalytic activity or selectivity over time, is still a major concern in the practice of industrial catalytic processes today. Poisons and promoters can change the rate-limiting step’s activation energy and impact a catalyst’s selectivity for the creation of specific products. Some of the mechanisms used for catalyst deactivation are:

- Sintering

- Fouling

- Coking

- Vapour-solid reactions

- Solid-state transformations

- Erosion

Industrial Uses

Heterogeneous catalysis is especially significant in the energy sector. For example, gasoline at a gas station has passed through on the order of ten catalysts on its route through the refinery. Future energy systems based on hydrogen or other energy carriers will also necessitate heterogeneous catalysis. In fact, many of the future issues associated with hydrogen production and fuel cells revolve around the development of new catalysts and catalytic processes. Technically, one of the most sought-after applications of heterogeneous catalysis in the manufacturing industry is the valuable synthesis of ammonia from its elements – nitrogen and hydrogen, also known as the Haber-Bosch process, which is promoted with iron as catalysts. An example of heterogeneous catalysis example is:

N2(g) + 3H2(g) → 2NH3(g) (Haber-Bosch Process)

The Haber cycle uses iron as a low-cost catalyst. It enables a reasonable yield in a reasonable amount of time. The other vital processes include the contact process for the production of sulfuric acid, which happens to involve the reaction between oxygen and sulphur dioxide, and is catalysed by vanadium oxides, or the Ostwald process for the synthesis of nitric acid, which primarily involves the reaction between ammonia and oxygen and is catalysed by an unsupported platinum-rhodium gauze.

4NH3 + 5O2 ⟶ 4NO+ 6 H2O + Heat

2NO + O2 ⟶ 2NO2

4NO2 + 2H2O + O2 ⟶ 4HNO 3 (Nitric Acid formation through Ostwald process)

Conclusion

This was all about heterogeneous catalysis, and its day-to-day applications in our lives. The development of novel materials that catalyse the manufacture of essential compounds in more selective and energy-efficient processes is a promising option for the chemical industry to reduce its energy consumption. Catalysts are used in most industrial chemical transformations, so developing novel materials that catalyse the creation of key compounds is a pressing necessity. An integrated strategy comprising fundamental experimental studies, theoretical modelling, and material evaluation under working catalytic circumstances aids in the efficient design of novel catalysts.

Profile

Profile Settings

Settings Refer your friends

Refer your friends Sign out

Sign out