A gear train is a mechanism that is composed of two or more gear like structures, those gears are like some disks with teeth at the periphery that mesh together. The prime purpose of the gear train is to increase the rotational speed or torque. The basic arrangement of the driver and the driven gears can decide whether the gear train can enhance its speed or torque. For increasing the output of a gear train or increasing the torque, a power source is needed to be directly connected to the smaller gears that are used to drive a larger gear.

Power Transmission Systems

The automobile transmission system can be referred to as a terminology of all the power transmission systems from the engine to the driving wheels. The main function of the transmission system is to transmit the power of the engine to the driving wheels increasing the torque or the speed. In a power transmission system, there is a rear driveshaft attached to a propeller shaft of the automobile. There is a final reduction gear that remains connected to the rear driveshaft, a pair of oil hydraulic clutches are there for transmitting the rear wheels or final reduction gear’s output. The main function of the power transmission system is transmitting or transferring the engine power to the driveshaft and the axle half shafts or rear wheels. The gears inside the transmission change a motor vehicle’s drive-wheel speed and the rotational speed in terms of engine speed and torque.

Power Transmission Systems-Gear Trains

The power transmission system in any vehicle usually includes a gearbox, rotary electric unit (that channelises its power via the gearbox ), an engine and a clutch. The clutch is provided in between the input and the output shaft to control the torque between them in the gearbox. A simple gear train usually uses two gears of two different sizes, the one attached to the motor is called the driver gear and the other one moved or turned by the driver gear is known as the driven gear.

Sometimes a gear train may include more than two gears- the gears present in between the driver and the driven gears are called the passive gears. The gear trains are of so many types- Simple Gear Trains, Compound Gear Trains, Reverted Gear Trains and Epicyclic Gear Trains. The simple gear trains are vastly used in cars, the compound gear trains are used in clocks (where a large number of speed changes are required). The reverted ones are used in automotive transmissions and industrial speed reducers; whereas the epicyclic ones are used in lathe back gears, pulleys, hoists and wristwatches. The Planetary Gear Train (PGT) has been used widely in the transmissions of automobiles, helicopters, aircraft engines, wind turbines and so on.

Power Transmission-Calculations

For Simple Gear trains-

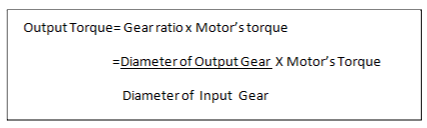

The mechanical advantage for the transmission is its high efficiency, its large amount of transmission and its compactness. To calculate the output torque produced by the simple gear, first, the gear ratio is calculated by dividing the output gear’s diameter by the diameter of the input gear. Then, the gear ratios are multiplied by the motor’s torque to find out the output torque.

To Calculate the Work Done per Minute-

The force (average torque) and the distance (angular displacement) or the radius or the shafts are multiplied.

Work done per minute = force× Distance

=Average torque× Angular Displacement

=T×(2πN/60)

Power(P) =T×(2πN/60) watts

P = Tω watts

Power Transmission Systems Examples

Out of the four types of Power transmission- Mechanical, Electrical, Hydraulic and Pneumatic; each of the power transmission systems is used for different purposes. The examples are given in the following-

Mechanical Power Transmission-

Gear drive, Turbo vortex drive, Belt Drive Chain Drive, Wheel Train etc.

Electrical Power Transmission-

The power transmitting system of electric power plants, electric transformers, generators where the energy can be transmitted in AC or DC forms.

Hydraulic Power transmission-

The hydraulic power transmission is hugely used in automobile factories for pulling heavy automobiles. This can also be used extensively for farm machinery, machine tools, printing presses and coal mining machinery.

Pneumatic Power Transmission-

The pneumatic power transmission can be used in various pneumatic devices where compressed air is generated and utilized to exert power and bring more mechanical advantages. Some of the instances are- pavement breakers, rock drills, bicycle pumps, paint sprayers, riveters, tire pressure gauges, jackhammers etc. They can also be used as air-compressors, air-brakes on buses, trucks or trains, Barostat systems used in Neurogastroenterology and for researching electricity.

Conclusion

From the above-mentioned analysis and discussion, the basic structure of the gear trains and the power generated or transmitted by them has been briefly stated. The mechanism of the gear trains, their types and their uses has been discussed too. The power transmission system, its mechanism, types with instances of its regular uses has also been mentioned.

Profile

Profile Settings

Settings Refer your friends

Refer your friends Sign out

Sign out