Although the Brayton cycle generally regulates as an open technique, which it does have to do if internal combustion is utilized, for thermodynamic analysis objectives it is commonly determined that the exhaust gas is reused in the air intake, stimulating estimation as an impenetrable operation. The engine Brayton cycle is titled after the famous American engineer whose name was George Brayton, who initially formulated it for usage in piston engines, although it was first recommended and licenced by Englishman John Barber in 1791. It is likewise occasionally called the Joule cycle. One category of the Brayton cycle is accessible to the environment and utilizes an inward combustion cabin; the other type is sealed and operates as the heat exchanger. Brayton cycle engines have distinct piston compressors and piston expanders, and the compressed air is warmed up by an eternal flame as it arrives at the expander cylinders. The first interpretation of the Brayton cycle engine was a steam engine, which blended fuel with air as it enters the compressor through a hectic surface carburettor.

Brayton Cycle

The Brayton cycle is a thermodynamic cycle utilized in some heat devices. Notably, it is utilized in gas turbine engines and jet engines. The Brayton cycle pertains to condensing ambient air, blending the atmosphere with energy, then provoking the combination, which broadens, performing work. In many Brayton cycle engines, hot air can be regained, warming up the small air that passes through. This boosts or increases efficiency because less fuel is compelled to warm up the fresh air. In physics phrases, this Brayton cycle comprises adiabatic compression and expansion and isobaric heating and chilling and authorizes boosted efficiency in some different cycles.

Some nuclear power plant compositions have evaluated the usage of the respectable Brayton cycle, such as the pebble bed modular reactor in South Africa and distinct molten salt reactors. This would compel the usage of active gases from the reactor core to strengthen the turbines. Nonetheless, the substantial research and improvement required to accomplish this goal have so far impeded achieving this goal. Extensively nuclear reactors utilize Rankine cycle steam engines, so current air-cooled prototypes must utilize this active gas to warm up water for usage in steam turbines.

Brayton Cycle Process

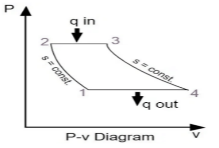

The Brayton Cycle Process includes or transpires in a modest gas turbine engine configuration, the air is brought out into a compressor where a pressure build-up arises. The turbocharger outcome airflow arrives at the combustion compartment, fuel is inoculated into the air and eruption occurs. The heated combustion commodities arrive at the gas turbine and expand, generating work. The task required to run the Brayton Cycle Process compressor is taken out from the turbine’s gross work output; the sediment can be utilized as the engine’s network production. The Brayton cycle models the progression by: 1 – 2 is the isentropic compression, 2 – 3 is the constant pressure heating, 3 – 4 is the isentropic expansion and 4 – 1 is the constant pressure warmth dissipation.

Brayton cycles are expressed in terms of pressure-volume and temperature entropy. For this reasonable configuration, the Brayton cycle defined pressure ratio exemplifies the elevated distress in the cycle halved by the low pressure in the Brayton Cycle process. Thermodynamic estimation of this cycle without considerable kinetic energy amends the thermal efficiency of the equation.

Brayton Cycle Efficiency

Brayton cycle efficiency is most susceptible to higher intake air weathers, which compel boosted work to compress the air before fuel injection and combustion. In addition, the development in ambient temperature will also lessen the power generation of the gas turbine. In the longer term, criteria to adapt thermoelectric cooling networks to soaring ambient weathers may be incorporated with measures to modify water supply, examined in more circumstances below. This is what we know about Brayton Cycle Efficiency.

The efficiency formula for the Brayton cycle in terms of pressure ratio is

nth = 1 – [1/ (PRk – 1/k)]

where PR is Pressure Ratio

k is adiabatic index

Principle of Brayton Cycle

According to the principle of the Brayton cycle, the air is reduced in a turbo compressor. The air is then varied with fuel and combustion under continual pressure circumstances in the combustion chamber. The occurring hot gas is broadened through a turbine to perform work. Most of the work generated in the turbine is utilized to jog the compressor, the rest can be utilized to jog auxiliary equipment and develop electricity. This is the principle of the Brayton cycle.

Conclusion

The Brayton cycle illustrates the standard prototype of air for the power cycle of a gas turbine. A reasonable gas turbine engine of the Brayton cycle comprises three central components: compressor, turbine and combustor. Common utilizations encompass stationary power plant electrical establishments and mobile power production engines for ships and aircraft. In power plant petitions, the power output of a turbine is utilized to furnish shaft power to navigate generators, helicopter rotors.

Profile

Profile Settings

Settings Refer your friends

Refer your friends Sign out

Sign out