Semiconductors and electronic circuits have caused a paradigm shift that cannot be ignored. There isn’t a single person on the planet who hasn’t used semiconductors in some capacity.

We will learn about semiconductors and how they work in this article. We will also discuss some semiconductor applications in daily life (the devices that resulted in the innovations we use today, such as radios, televisions, automobiles, air conditioners, computers, mobile phones, and all modern communication devices, as well as many household appliances.)

Explain the Application of Semiconductors

It is well understood that the conductivity of any material is primarily determined by the movement of electrons, as electrons carry current through the material. Furthermore, it is known that the nucleus has a positive charge while the electrons have a negative charge. As a result, the nucleus and electrons are attracted to one another.

As a result, electrons must escape this attraction in order for current to flow through the material.

Some electrons exist in two bands in solid materials: conduction bands and valence bands. Electrons in the conduction band can easily move within the material without leaving their crystals. Because they are closer to the nucleus, electrons in the valence band are confined and do not conduct current.

On the one hand, there is no separation between the valence band and the conduction band in conductors. The electrons in the two bands are intertwined, allowing valence electrons to easily move between the two bands. Insulating materials, on the other hand, have a large separation between the two bands.

Last but not least, in semiconductors, the separation between the two bands is average. Thus, valence electrons can jump to the conduction band if they acquire enough energy to pass through the separator, allowing the semiconductor to deliver electricity.

Hall effect in Semiconductor Application

Lorentz force is primarily responsible for the Hall effect. We all know that when we place a current carrying conductor inside a magnetic field, the conductor experiences a mechanical force in the direction determined by the magnetic field’s direction and the direction of the current in the conductor. A flow of charge is represented by an electric current.

It is entirely due to the flow of electrons in metal, but it is also due to the flow of free electrons and holes in semiconductors. In a semiconductor, holes move in the direction of conventional current, while free electrons move in the opposite direction. Because electrons have charge, they experience a force as they flow through a conductor in a magnetic field.

During flow, electrons are diverted to one side of the conductor due to this force. As the following charges are shifted to one side of the conductor, a tiny potential difference may appear across the conductor’s cross-section. This entire phenomenon is known as the hall effect.

Wide band gap Semiconductor Applications

Wide-band-gap semiconductors have the physical properties to revolutionise high-frequency solid-state power devices.

The rapid development of GaN microwave transistors, which opens up new opportunities for many applications, is an outstanding example.

The ability of the AlGaN / GaN heterostructure to form a high-electron-mobility transistor (HEMT) has piqued the interest of many research groups around the world, resulting in tremendous progress as represented by a power density 30 times that of conventional GaAs field effect transistors.

Types of Semiconductors

Semiconductors are classified into two types: intrinsic and extrinsic.

Intrinsic

Semiconductors in their pure form are known as Intrinsic Semiconductors, and they are only marginally useful because they are neither good conductors nor good insulators.

The valence shell (of a semiconductor material) carries an equal number of holes and electrons in the pure forum (silicon has 4 valence electrons).

Extrinsic

Impurities (such as boron, antimony, and so on) are added to pure semiconductors through a process known as doping, which increases the conductive behaviour of semiconductors; such doped semiconductors are known as Extrinsic Semiconductors. (We’ll get to doping in a minute.)

Conclusion

It is well understood that the conductivity of any material is primarily determined by the movement of electrons, as electrons carry current through the material. On the one hand, there is no separation between the valence band and the conduction band in conductors. The electrons in the two bands are intertwined, allowing valence electrons to easily move between the two bands. Last but not least, in semiconductors, the separation between the two bands is average. We all know that when we place a current carrying conductor inside a magnetic field, the conductor experiences a mechanical force in the direction determined by the magnetic field’s direction and the direction of the current in the conductor. It is entirely due to the flow of electrons in metal, but it is also due to the flow of free electrons and holes in semiconductors. In a semiconductor, holes move in the direction of conventional current, while free electrons move in the opposite direction.

Stress and Strain

Stress:

Stress is defined as the force applied to a material divided by the cross-sectional area of the substance.

∂=F/A0

∂=stress

F=force

A0=initial cross-sectional area

Strain:

Strain is the material’s deformation or displacement as a result of applied stress.

ξ=Ln-L0/L0

ξ=strain

Ln=new length

L0=initial length

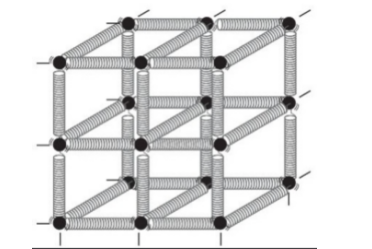

Hooke’s Law

Hooke’s law is a law of elasticity developed by the English scientist Robert Hooke in 1660, which states that for relatively mild deformations of an object, the displacement or amount of a deformation is precisely proportional to the deforming force or load. When the load is removed under these conditions, the item returns to its original shape and dimensions. The fact that minor displacements of their constituent molecules, atoms, or ions from normal locations are proportional to the force that generates the displacement explains the elastic behaviour of solids according to Hooke’s equation.

Stretching, compressing, squeezing, bending, and twisting can all be used to distort a solid. According to Hooke’s law, a metal wire exhibits elastic behaviour when stretched by an applied force since the modest increase in its length doubles each time the force is doubled. Hooke’s law asserts that the applied force F equals the displacement or change in length x times a constant k, or F = kx. The value of k is determined not only by the type of elastic material but also by its dimensions and shape.

Formula of Hooke’s Law

As long as the load does not exceed the material’s elastic limit, many materials will obey this law of elasticity. Linear-elastic or “Hookean” materials are those for which Hooke’s law is a useful approximation. Hooke’s law states that stress is proportional to strain in a direct relation.

Hooke’s law is expressed mathematically as:

F=−kx

Here,

x is the displacement of the spring’s end from its equilibrium position

F is the restoring force exerted by the spring on that end

k is a constant called the rate or spring constant

Elastic Modulus

We know that when an elastic material is distorted by an external force, it maintains an internal resistance to resist the deformation and returns to its original state once the external force is removed.

The various types of elastic moduli are as follows:

- Young’s Modulus: Young’s modulus is a property of an object that allows it to endure changes in its length when longitudinal tension or forces, such as compression, are applied. The longitudinal stress divided by the object’s strain equals the Young’s modulus. The letter Y symbolises Young’s Modulus.

- Shear Modulus: The shear modulus, also known as the Modulus of Rigidity, is the ratio of shearing stress to shearing strain. The letter ‘G’ symbolises Shear Modulus.

- Bulk Modulus: The ratio of hydraulic stress to associated hydraulic strain is known as bulk modulus. The letter ‘B’ symbolises Bulk Modulus.

Conclusion

Experiments can be used to determine the relationship between stress and strain for a specific material under tensile tension. A test cylinder or wire is stretched by an applied force in a conventional tensile property test. The applied force required to create the strain, as well as the fractional change in length (the strain), are both recorded.

The applied force is gradually raised in steps, with the length of each step being recorded. The stress (which is the same magnitude as the applied force per unit area) and the strain produced are represented on a graph.

Profile

Profile Settings

Settings Refer your friends

Refer your friends Sign out

Sign out